WIDIA - Полный каталог инструмента - 2017

для размещения заказа - zakaz@widiahanita.ru

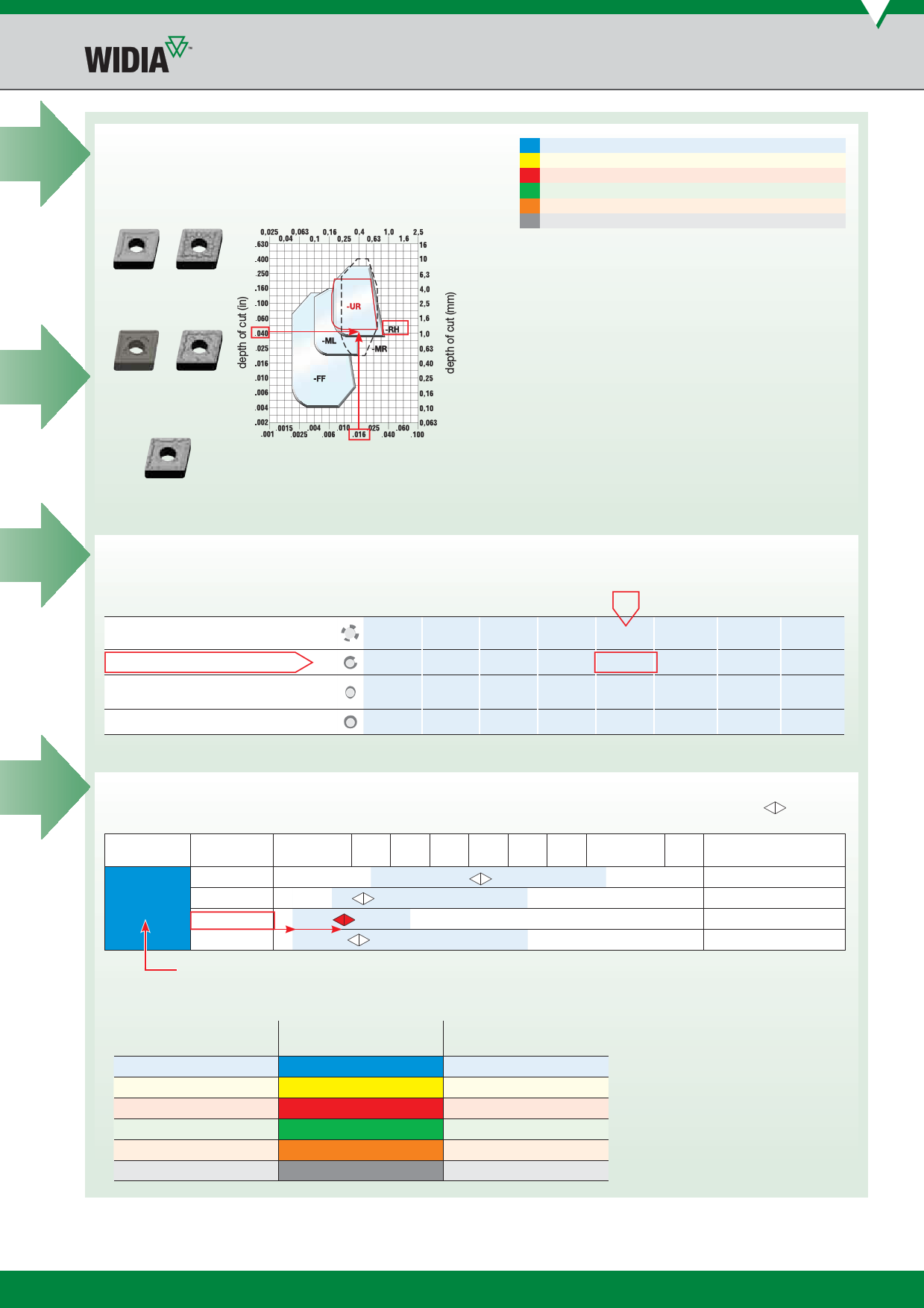

WIDIA™ Victory™ • High-Performance Inserts

Insert Selection System

Step 1 • Select the insert geometry

Negative Inserts

feed rate (mm/rev)

-RH -UR

Roughing

P Steel

M Stainless Steel

K Cast Iron

N Non-Ferrous

S High-Temp Alloys

H Hardened Materials

-ML -MR

Medium

Machining

-FF

Finishing

feed rate (in/rev)

Step 2 • Select the grade

cutting condition

heavily interrupted cut

lightly interrupted cut

varying depth of cut,

casting, or forging skin

smooth cut, pre-turned surface

-FF

WP15CT

Negative Insert Geometry

-ML -MR -UR

WP25CT

WP35CT/

WP25CT

WP35CT

-RH

WP35CT

Positive Insert Geometry

-FP -MU -MP

WP25CT/

WS25PT

WP35CT

WM35CT

WP15CT WP25CT WP25CT WP35CT WP35CT WP25CT WP25CT WP25CT

WP15CT WP15CT WP15CT WP25CT WP25CT WP15CT WP15CT WP15CT

WP15CT WP15CT WP15CT WP25CT WP25CT WP15CT WP15CT WP15CT

Step 3 • Selecting the cutting speed

Low-Carbon (<0.3% C) and Free-Machining Steel

material

group

grade

135 180 225 275 320

WP15CT

P0/P1

WP25CT

WP35CT

WS10PT

WIDIA Material Group Selection Guide:

To optimise speed recommendations, material subgroups have

been added to each of the six workpiece material groups.

speed — m/min

360 410

455

material

steel

stainless steel

cast iron

non-ferrous materials

high-temp alloys

hardened materials

material group

ISO code

P

M

K

N

S

H

number of material

subgroups

1–6

1–3

1–3

1–8

1–4

1

Starting Conditions

495 m/min

395

275

210

280

zakaz@widiahanita.ru

www.widiahanita.ru

B9