WIDIA - Полный каталог инструмента - 2017

для размещения заказа - zakaz@widiahanita.ru

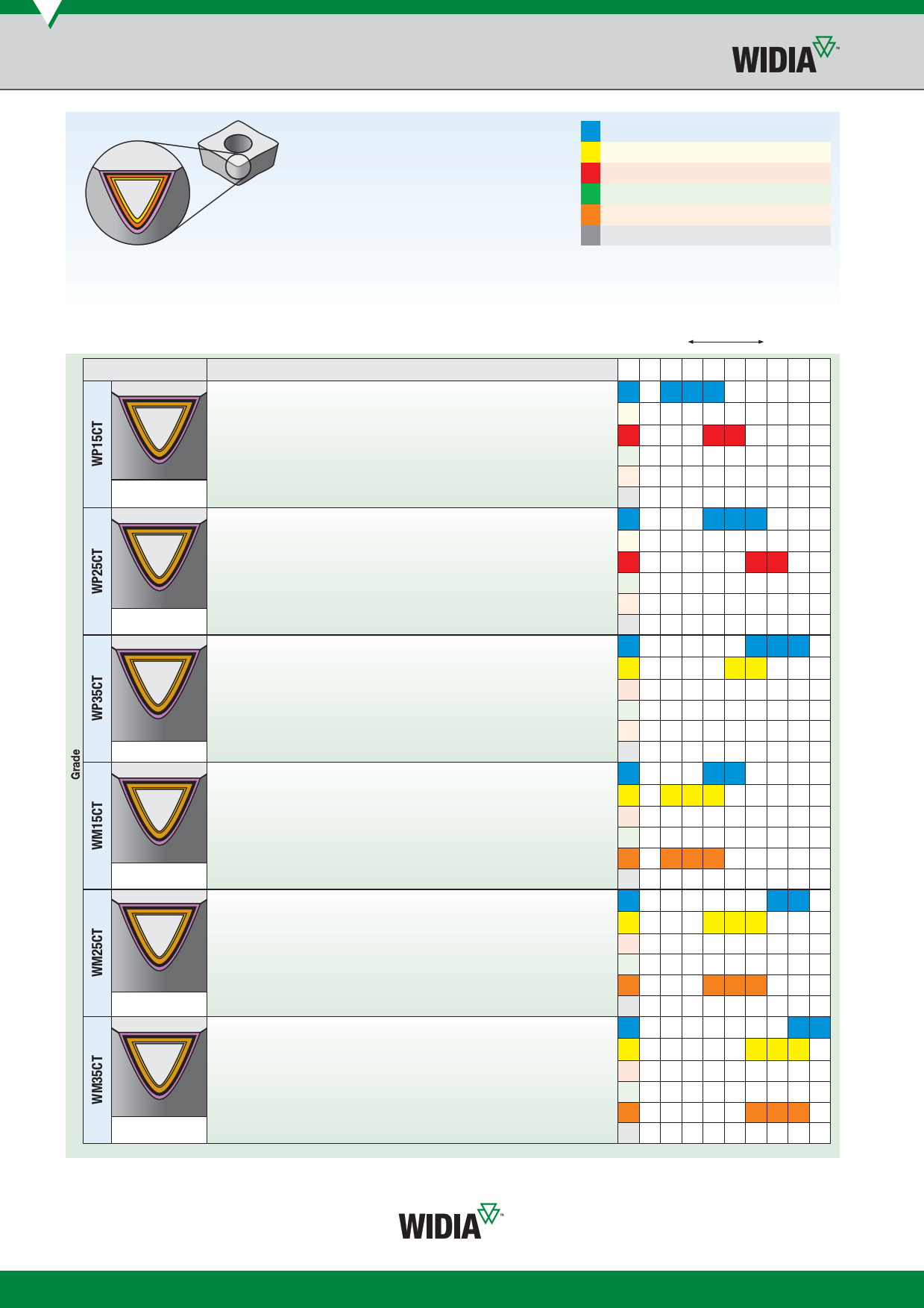

WIDIA™ Victory™ • High-Performance Inserts

Grades and Grade Descriptions

Coatings provide high-speed

capability and are engineered

for nishing to heavy roughing.

P Steel

M Stainless Steel

K Cast Iron

N Non-Ferrous

S High-Temp Alloys

H Hardened Materials

Coating

HC-P15

HC-P25

Grade Description

Coated carbide. MT-CVD/CVD — TiN-TiCN-Al2O3-ZrCN. Good balance

of wear resistance and toughness properties. High productivity machining

on smooth to lightly interrupted cuts. For steels.

wear

resistance

toughness

05 10 15 20 25 30 35 40 45

P

K

P

Coated carbide. MT-CVD/CVD — TiN-TiCN-Al2O3-ZrCN. Good toughness properties.

Excellent first choice for steel machining, high productivity metal removal for all but the

K

harshest interrupted cuts.

Coated carbide. MT-CVD/CVD — TiN-TiCN-Al2O3-ZrCN. Proven on all roughing

and heavy roughing operations, wet or dry, on interrupted and uninterrupted cuts.

P

M

HC-P35

Coated carbide. MT-CVD/CVD — TiN-TiCN-Al2O3-ZrCN. High degree of

wear resistance and good resistance to depth-of-cut notching for long

tool life in finishing to medium turning applications.

HC-M15

Coated carbide. MT-CVD/CVD — TiN-TiCN-Al2O3-ZrCN. Good balance of

wear resistance and toughness properties. Light and medium machining.

For austenitic stainless steel AISI series.

HC-M25

Coated carbide. MT-CVD/CVD — TiN-TiCN-Al2O3-ZrCN. Good toughness

and wear resistance balance. For medium to roughing operations with light

and heavily interrupted cuts.

HC-M35

P

M

S

P

M

S

P

M

S

B26

zakaz@widiahanita.ru

www.widiahanita.ru